как мы

делаем кофе

Принципы

три ключевых компонента

производства

Лучшее в мире оборудование

Автоматизация

Многоступенчатый контроль качества

Наша цель — максимально раскрыть вкус каждого лота с помощью обжарки и делать это стабильно от партии к партии. Для этого мы продумали все этапы производства — от хранения до упаковки.

В начале

Входящий

Контроль

Каждый новый лот зеленого кофе проходит через нашу лабораторию, где мы оцениваем его по физическим (влажность, плотность, водная активность) и вкусовым параметрам (оценка по форме SCA — для этого у нас 10 Q-грейдеров в компании).

- Влажность

- Плотность

- Водная активность

- Аромат

- Букет

- Послевкусие

- Кислотность

- Интенсивность

- Тело

- Плотность

- Однородность

- Баланс

- Чистая чашка

- Сладость

- Дефекты

- Общая оценка

- Итоговая оценка

Хранение

Храним Зеленый

Кофе Правильно

Зеленый кофе тоже подвержен старению и важно правильно его хранить.

Мы постоянно поддерживаем на складе нужную температуру с помощью системы климат-контроля. А для регулирования уровня влажности используем промышленные увлажнители, которые ежедневно распыляют в воздухе до 500 литров воды.

Влажность

55%

Температура

16°С

Оборудование

Работаем на лучшем

оборудовании

В мире

Для обеспечения стабильной обжарки от партии к партии мы используем лучшие в мире ростеры брендов Loring и Giesen.

Разный объем загрузки наших ростеров позволяет нам каждый день обжаривать разный кофе: от редких микролотов до эспрессо-смесей для кофемашин.

Автоматизация

IT-решения

Для Идеального

Результата

Мы используем два типа программного обеспечения для обжарки:

1 тип

Для записи графиков обжарки в течение дня, сравнения их с референтными обжарками и контроля качества. Эта программа называется Cropster.

2 тип

Системы повторения обжарок, установленные на каждом ростере. Они гарантируют, что вкус лота, который вы регулярно заказываете, не будет отличаться.

Очистка

Убираем все

Дефектные зерна

После обжарки мы очищаем кофе с помощью оптических колорсортеров SOVDA — первых в мире, разработанных специально для обжаренного кофе. Они фотографируют каждое зерно и удаляют все дефектные зерна: сколотые, квакеры и другие.

Упаковка

Упаковываем

кофе в азотной

среде

Мы упаковываем наш кофе в

азотной среде, с полным

отсутствием кислорода,

что позволяет хранить его в два

раза дольше без изменения вкуса.

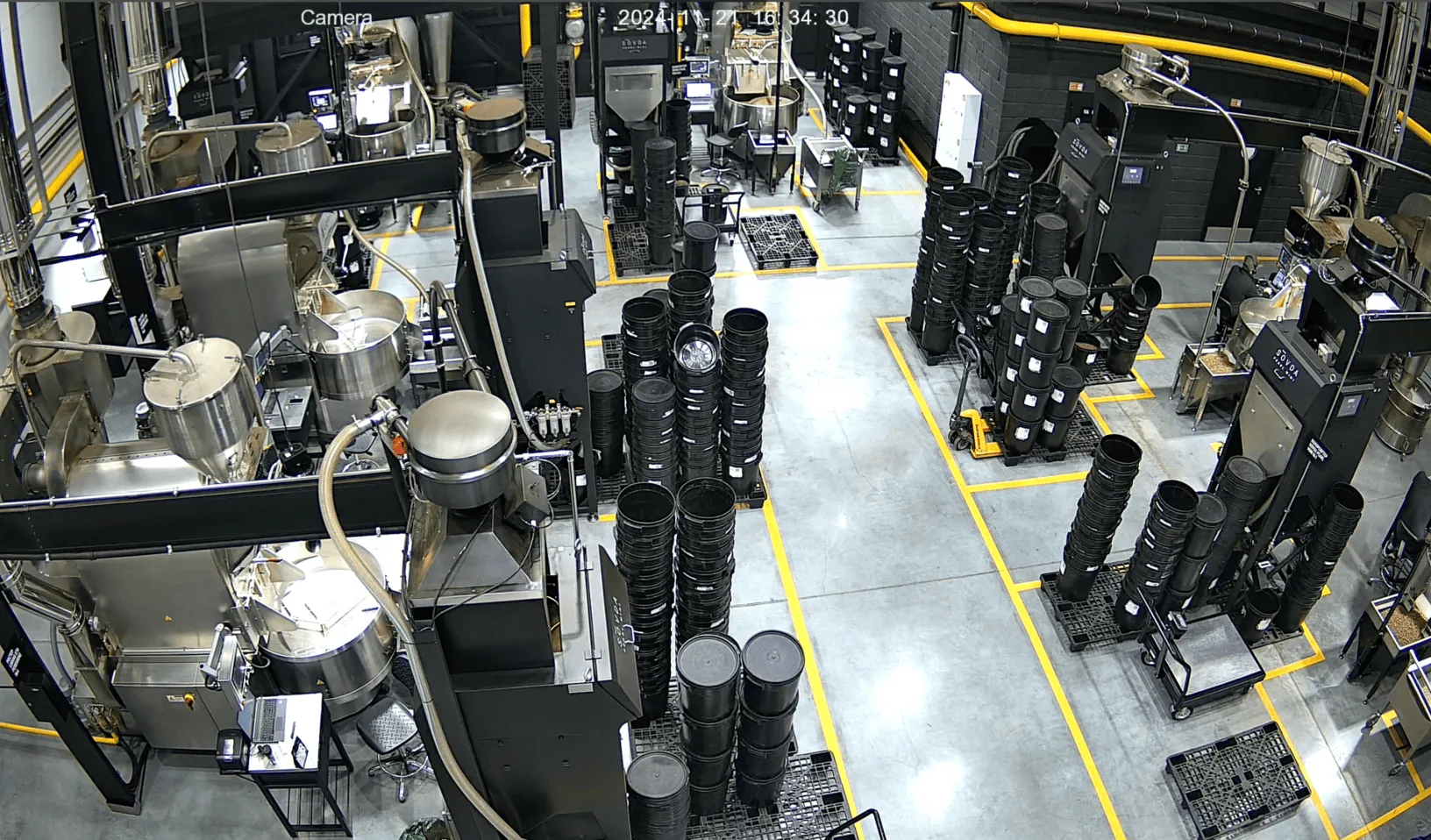

ПРОЗРАЧНО

Полная

Открытость

Мы запустили круглосуточную трансляцию из нашего цеха обжарки и склада зеленого кофе, потому что нам нечего скрывать — у нас всегда полный порядок.

Контроль

7 контрольных точек

для проверки

каждой партии

Общее время обжарки ①

Градус загрузки ②

Градус выгрузки ③

Время развития после «крэка» ④

Цвет по колориметру ⑤

Процент потери веса ⑥

Вкус ⑦

Первые четыре контрольных точки мы проверяем с помощью программы Cropster.

Цвет зерна мы контролируем лазерными колориметрами ColorTrack, чтобы убедиться в нужной степени обжарки.

Уникальный QR-код

на каждой пачке

Наша автоматизированная система присваивает каждой упаковке кофе уникальный QR-код и записывает в него всю информацию.

Это позволяет нам четко комплектовать каждый заказ без ошибок и знать все о каждой пачке, которую отправили вам: условия хранения, график обжарки, результат контрольного каппинга, время упаковки и отправки.

Экскурсия

Посмотрите,Как устроеноПроизводство

Игра

Победи

колорсортер

Колорсортер фотографирует каждое зерно и удаляет дефектные зерна.

Мы предлагаем вам выбрать дефектные зерна, цвет которых отличается от других. Кликайте на такие зерна, чтобы сформировать идеальную партию кофе.